“Comtest is extremely flexible, forward-thinking and fast.

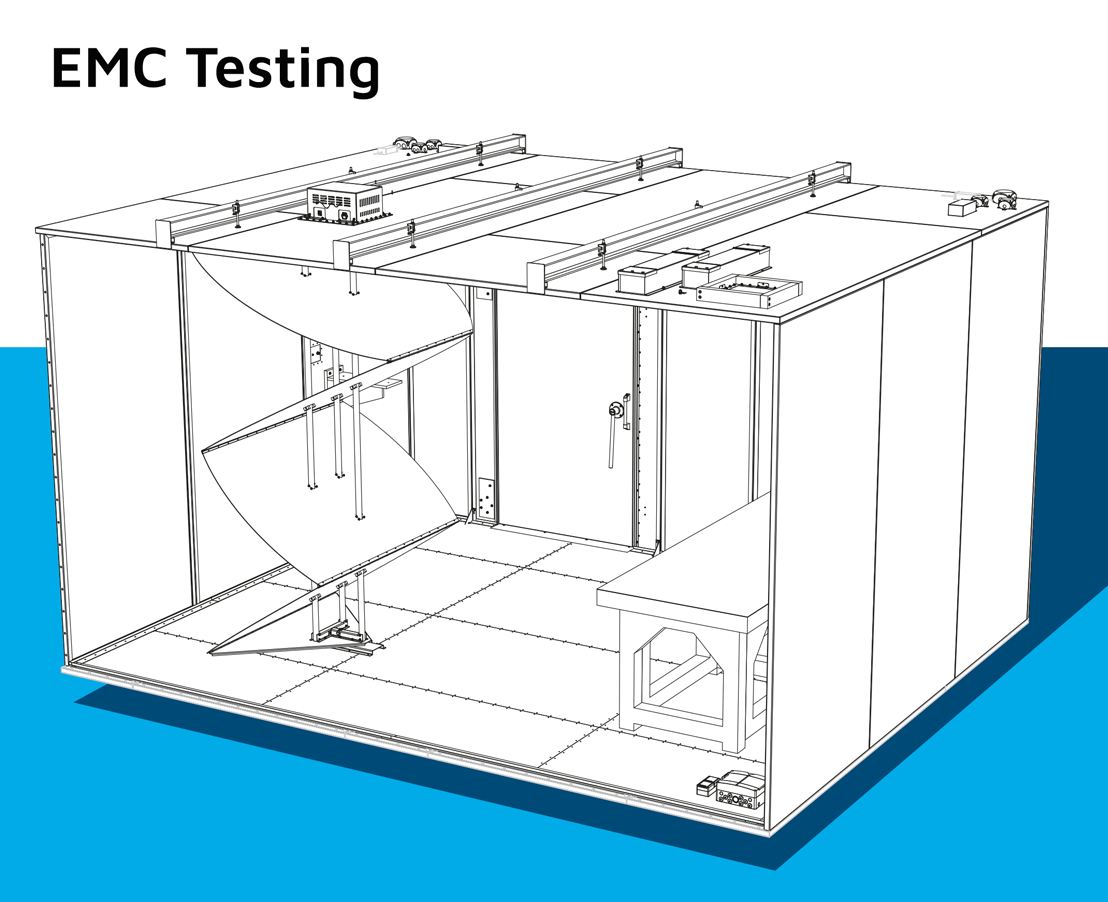

We are satisfied with our EMC chamber, which is set up to

provide us with load possibilities far beyond anything possible

with third-party testing solutions. This makes our test execution

very close to real-life usage of our products.”

We are Comtest

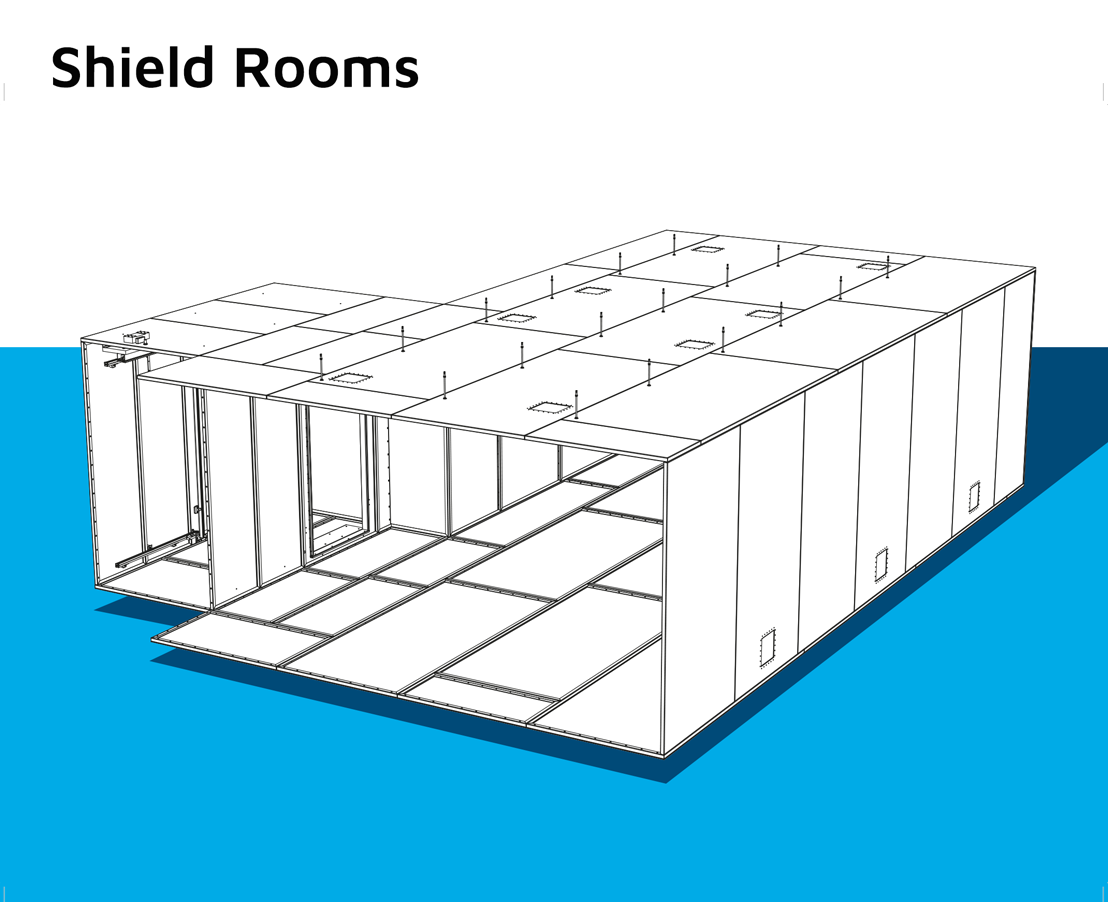

We are Comtest. We design, build and maintain worry-free, compliant EMC and Antenna test chambers and RF-Shielded Rooms. As a family business for 38 years, we like to focus on the human factor of technology. We believe that great technological solutions only work if they enable the people who use them to be successful at what they want to achieve. That’s why you and your challenges are at the heart of everything we do. We are committed to creating chamber solutions that will fast-track your products to your market without compromising on high-quality output. Let’s work together and make our solution your success.